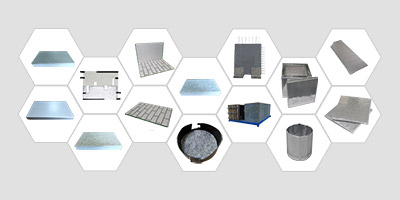

Aerogel composite insulation board

Thermal conductivity: Type I ≤ 0.008W/(m · K), Type II ≤ 0.012W/(m · K).

Product feature: The unique protective layer can solve the high loss/pain points during the external adhesive construction process!

Prefabricated sandwich exterior wall components can directly replace this material; Significant advantages - cost savings!

The performance of the product is 1.5% -5% higher than that of traditional materials in building yield; According to the following table, a construction area of 200000 square meters for the exterior wall can directly save 34.8 million yuan in cost, and at least increase the usable area of the set by 3000 square meters!

For resettlement housing, the common people have benefited and gained tangible benefits!

Eliminate fire hazards; Strengthening the strategy of market sales for commercial housing!

| Reference explanation for cost related data comparison of prefabricated sandwich exterior wall components |

| product | Wall thickness (mm) | Component cubic conversion to square meters (㎡)

| Estimate the cost of sandwich insulation exterior wall components (yuan/m ³)

| Total square meter cost of finished sandwich exterior wall components (yuan/m ³) | Comparison results and advantages |

| XPS | 200mm concrete structure+100 extruded board+60mm cement outer sheet | =360mm thickness ≈2.77㎡

| Approximately 4500 yuan/cubic meter | 1624 yuan | Air gel composite insulation board is used for sandwich components of exterior wall to replace traditional XPS, saving 174 yuan per square meter |

| Aerogel composite insulation board | 200mm concrete structure+30mm aerogel composite insulation board+60 cement outer sheet | =290mm thickness ≈3.44㎡ | About 5000 yuan/cubic meter | 1450 yuan |

The above data is for reference only

|